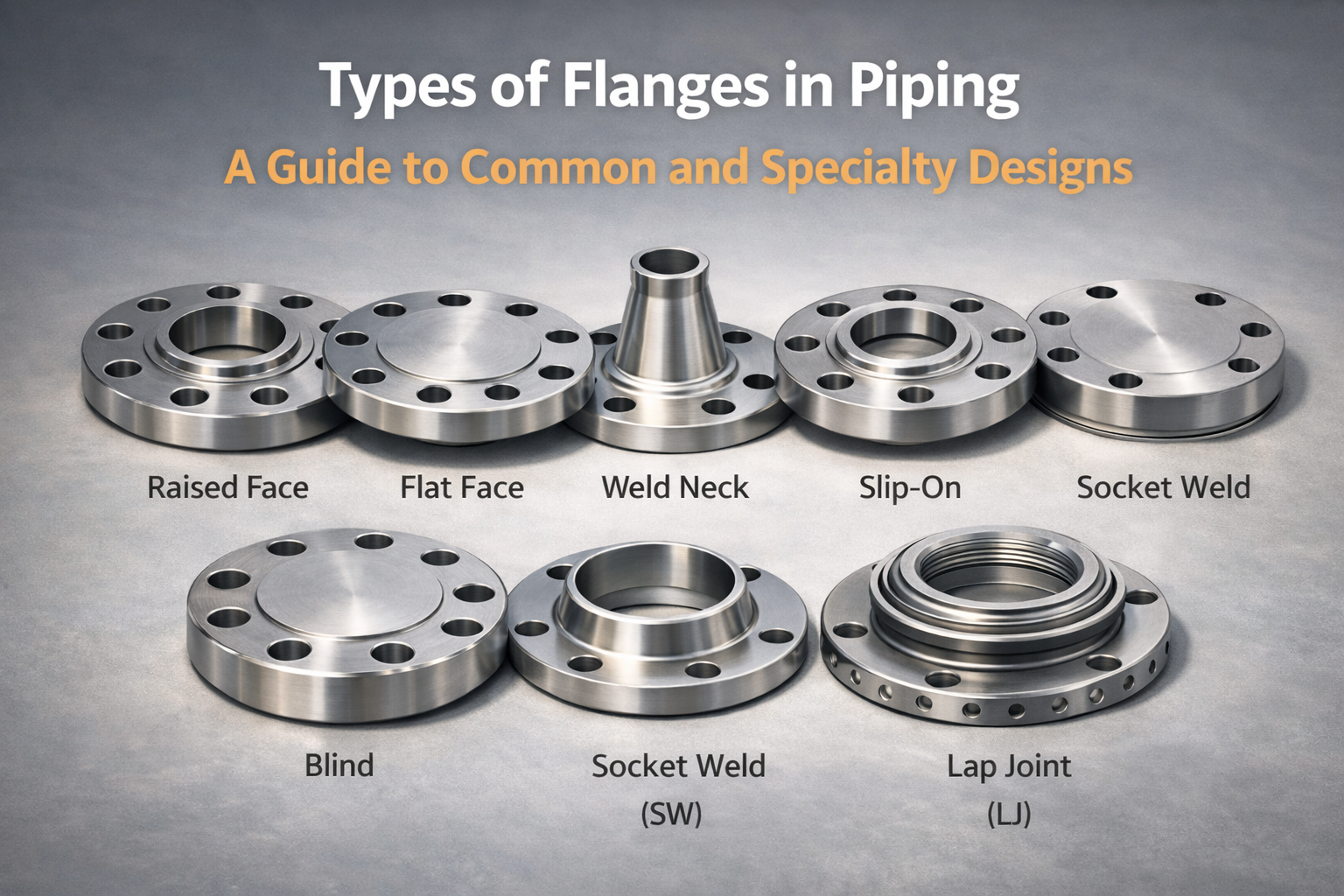

In piping systems, not all flanges are the same. The type of flange you choose affects installation, pressure handling, and maintenance. This guide explains the common types of flanges and their specific uses. Knowing the differences helps you specify the correct part for your project.

Common Flange Types and Their Uses

Each flange type has a distinct design for a particular purpose.

1. Weld Neck Flange

This flange has a long tapered hub that is welded to the pipe.

- Use: For high-pressure and high-temperature systems. The weld neck design reduces stress at the joint. It is common in oil and gas, refineries, and critical process lines.

- Standards: ANSI B16.5, ASME standards.

2. Slip-On Flange

This flange slides over the pipe and is then welded on both the inside and outside.

- Use: For lower pressure applications. It is easier to align than a weld neck and costs less. It is common in water lines, utility systems, and less critical services.

- Note: Its strength is lower than a weld neck flange.

3. Blind Flange

This is a solid disc with no bore. It is used to close off the end of a piping system or a vessel opening.

- Use: For isolating a section of pipe for maintenance, or for future expansion. It must withstand significant bolt stress.

4. Socket Weld Flange

This flange has a socket for the pipe to fit into. A fillet weld seals the connection.

- Use: For small-diameter, high-pressure pipes (typically under 4 inches). It provides good flow and is stronger than a slip-on flange.

5. Lap Joint Flange

This flange is used with a stub end. The flange rotates around the stub end, which is welded to the pipe.

- Use: In systems requiring frequent disassembly or where pipe alignment is difficult. The flange can rotate to line up bolt holes easily. Common in food processing or systems with alloy piping.

6. Threaded Flange

This flange has internal threads that screw onto a pipe with matching external threads.

- Use: For low-pressure, non-critical services where welding is not allowed (e.g., some explosive areas). It is not suitable for high stress or temperature cycling.

Specialty Flange Types

Some applications require unique designs.

- Spectacle Blinds (Line Blinds): A single piece flange with a solid end (blind) and a ring end (spacer). It is installed between two standard flanges to positively isolate a section of line.

- Orifice Flanges/Unions: Used for measuring the flow rate of liquids or gases. They have jack-screw holes and are assembled with an orifice plate.

- Long Weldneck (LWN) Flanges: A longer version of a standard weld neck. Used for heavy-wall pipe, vessel connections, or for butt-weld fittings.

- Studding Outlets (Pad Flanges): A small flange welded to a pipe or vessel to allow for a future connection.

- Reducing Flange: Used to connect a larger pipe to a smaller one, or to connect to different-sized equipment nozzles.

How to Choose a Flange Type: Quick Reference

This table summarizes key selection factors.

| Flange Type | Best For Pressure | Ease of Alignment | Ease of Installation | Common Applications |

| Weld Neck | High | Moderate | Requires skill | Refineries, HP Steam, Process Lines |

| Slip-On | Low to Medium | Easy | Easier, 2 welds | Water, Utilities, HVAC |

| Blind | All (as rated) | Easy | Easy | System Isolation, End Closures |

| Socket Weld | High (Small Bore) | Easy | Moderate | Instrument Lines, Small HP Lines |

| Lap Joint | Medium | Very Easy | Requires Stub End | Frequent Disassembly, Alloy Systems |

| Threaded | Low | Easy | Very Easy | Air, Water, Non-Critical Services |

Important: Face Types and Standards

The flange type is only part of the specification. You must also specify:

- Facing: The sealing surface (e.g., Raised Face (RF), Flat Face (FF), Ring-Type Joint (RTJ)). An RTJ Face is critical for high-pressure API applications.

- Standard: This dictates dimensions and pressure ratings. Common standards are ASME/ANSI B16.5, API 605/6A, MSS SP-44, and DIN or JIS for international projects. Mixing standards can cause bolt misalignment and sealing failure.

Frequently Asked Questions

Q: What is the strongest type of flange?

A: The weld neck flange is generally considered the strongest for high-stress applications due to its tapered hub and butt-weld connection.

Q: Can I replace a weld neck flange with a slip-on flange?

A: Not without reviewing the design. Slip-on flanges have a lower pressure rating and fatigue strength. The change may require engineering approval.

Q: What is a “Series A” or “Series B” flange?

A: These refer to ANSI B16.47 large-diameter flanges (NPS 26 and larger). Series A (MSS SP-44) is typically heavier. Series B (API 605) is lighter. They have different bolt patterns and are not interchangeable.

Q: Do you supply all these flange types?

A: Yes. We supply all common types and specialty flanges like spectacle blinds, orifice unions, and long weldnecks in materials from carbon steel to exotic alloys.

Conclusion

The right flange type depends on pressure, fluid, installation needs, and maintenance plans. Using the wrong type can lead to leaks or failure.

If you need help determining the correct flange type, material, or standard for your piping specifications, we can assist. Our experience covers all common and specialty types.

Submit your flange specifications for a quote or technical review here: http://texasflange.com/lp12/